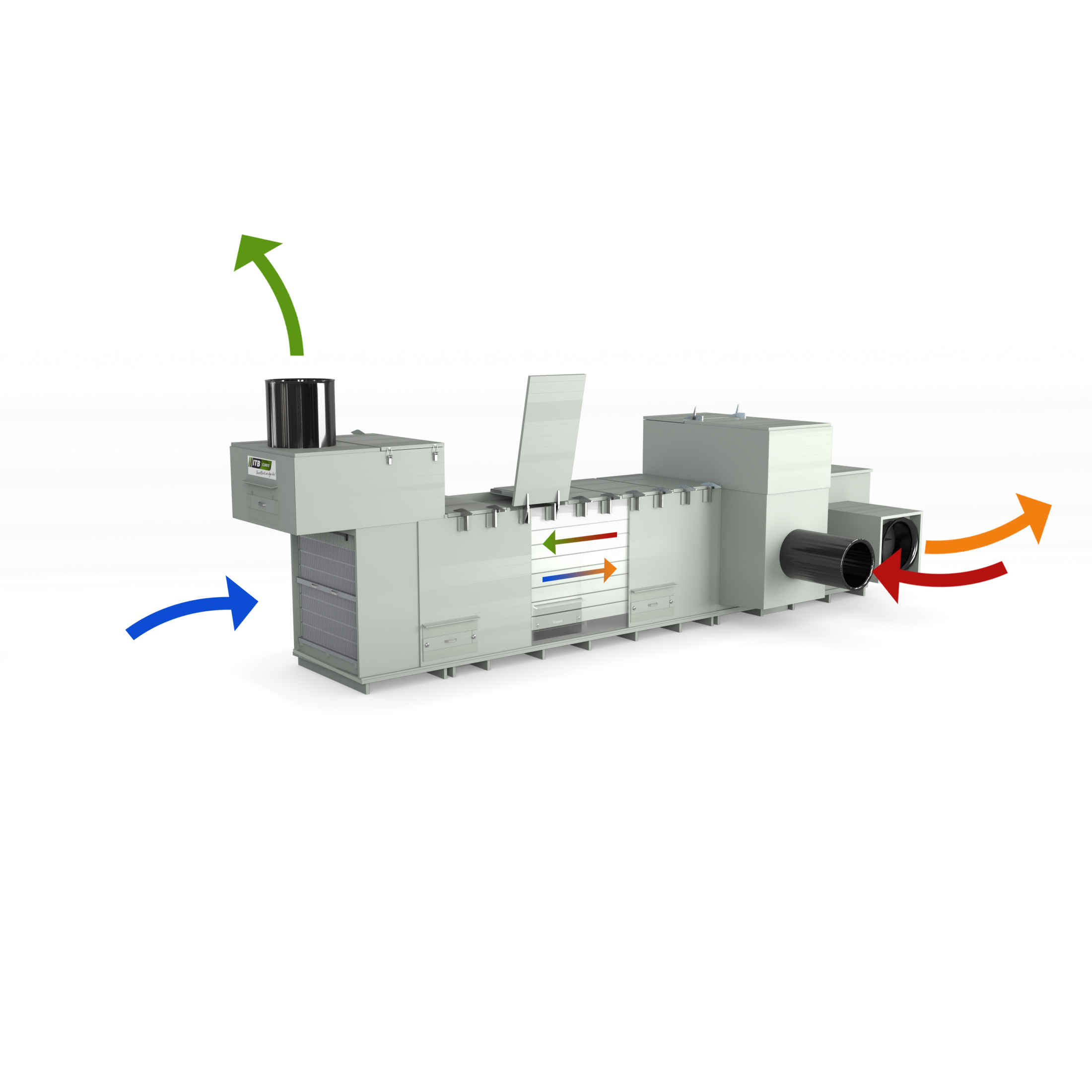

Heat exchangers are devices used to transfer heat from one fluid to another. In this case, the heat exchanger is used to cool the pork blood as it is collected from the slaughterhouse. The SACOME corrugated tube heat exchanger is designed to be highly efficient, with the corrugated design allowing for more heat transfer than a smooth tube design.

One of the key benefits of using a heat exchanger in this process is that it can help to reduce the risk of bacterial contamination. As the pork blood is cooled, any bacteria present in the blood are also cooled, which can slow their growth and prevent them from multiplying rapidly. This can help to ensure that the blood remains safe to use in further processing.

Another important consideration in the design of the heat exchanger is the need for hygienic operation. Any equipment used in the food industry must be designed with hygiene in mind, to prevent the risk of contamination. In this case, the heat exchanger is designed to be easy to clean and sanitize, with smooth surfaces and no crevices or other areas where bacteria can accumulate.

To further enhance the safety and hygiene of the process, SACOME also offers heat and moisture exchangers and bacterial/viral filters (HMEFs and BVFs) that can be used in conjunction with the heat exchanger. These filters are designed to remove contaminants from the air, helping to prevent the spread of airborne bacteria and viruses. By using a combination of heat exchangers and filters, food manufacturers can ensure that their processes are as safe and hygienic as possible.

In conclusion, the SACOME corrugated tube heat exchanger is an essential component in the cooling of pork blood for use in the food industry. Its efficient design helps to reduce the risk of bacterial contamination, while its hygienic construction ensures that the process is safe and sanitary. And with the addition of HMEFs and BVFs, food manufacturers can further enhance the safety and quality of their processes, providing consumers with the assurance that the products they are consuming are safe and healthy.